Smart Cameras Using Embedded FPGA Programming

The future belongs to “embedded Vision” — a networked, decentralized image processing of hard- and software in one housing. With VisualApplets Embedder, this is already achievable today. The solution for real-time image processing in FPGA devices such as industrial cameras is easy to integrate and operate. End users and image processing hardware manufacturers program on software applets tailored to their applications and industries with Embedder directly on the device’s FPGA in almost no time.

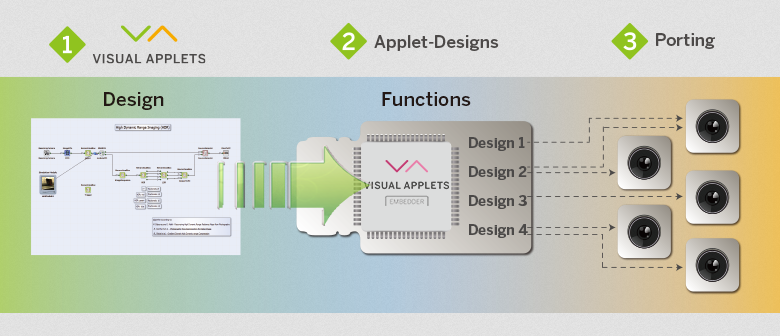

To accomplish this, they use the VisualApplets graphical development environment as the basis for Embedder, without using a labor-intensive hardware description language. In 2006, it was awarded the VISION Innovation Prize. With VisualApplets, they develop an unlimited number of individual and industry-specific image processing applications as applet designs.

To create an applet design, they flexibly combine by drag-and-drop operators which represent over 200 image processing functions to create a data flow model. The model is synthesized into a program code (bitstream) from which the FPGA is configured. VisualApplets supports users with unique tools for automatic error recognition, notification, and correction, as well as an intuitive, image-based high-level simulation.

VisualApplets makes it possible to use standard designs, to create proprietary image processing designs as data flow models or to individualize for customer groups.

|

On the hardware side, Embedder makes it possible to quickly adapt the integration design to new devices after the initial implementation, and to construct different product lines using image processing designs. In so doing, Embedder makes FPGA devices intelligent and reduces their time to market considerably. This innovative “embedded vision” solution has arrived on the market and has been honored numerous times as an integral component of Baumer’s LX VisualApplets camera series.

Development of complex applications directly on the device

Existing device hardware can easily be equipped with embedded VisualApplets technology so that a large part of the image pre-processing can be calculated on the device’s FPGA, conserving resources. Alongside image processing solutions, it is also possible to program and process data signals using VisualApplets. Signal in- and outputs as well as connections to external digital peripherals, such as PLC, lighting, rotary encoders and other control devices, are directly programmable in the device using VisualApplets.

|

VisualApplets verifies Embedder’s implementation process. Has the installation effort been accomplished for one hardware platform, it is possible with the development environment to create every type of image processing design as often as desired. Designs can then be very easily adapted for new device platforms or ported onto compliant devices using VisualApplets’ user interface. FPGA device manufacturers can allow their customers to program applications on the devices by themselves.

During installation, the new Embedder platform is integrated into a pre-installed version of VisualApplets. Any number of Embedder platforms can thus be added to VisualApplets.

Raise the added value of FPGA devices in image processing with Embedder

Your economical benefits

- Third-party hardware such as cameras can be easily equipped with embedded VisualApplets technology. For the most part, image pre-processing takes place on the device's FPGA

- Preprocessing tasks in real time, such as image improvement, data reduction, and process monitoring raise the throughput and reduce system costs

- Inputs and outputs, as well as connections to further external digital interfaces such as PLC, lighting, and other devices, can be integrated with Embedder and programmed directly using VisualApplets from third-party equipment

- Expert FPGA hardware programming knowledge is not required since the VisualApplets graphical development environment allows intuitive FPGA programming via data flow models, making Embedder interesting for end-user programming.

- Thanks to the FPGA devices' programmability, manufacturers and end users remain flexible when demands change

- End users profit from better know-how protection, since image processing functions can be implemented independent from the camera manufacturer.

How does it increase the throughput by VisualApplets Embedder? This is shown in this video by camera manufacturer Baumer to simplify the system setup and to reduce system costs, which uses the solution in its LX VisualApplets cameras with integrated image pre-processing.

Embedder opens up access to new markets and business possibilities for manufacturers of cameras and image processing devices in no time. Users get “smart” devices that afford them the highest possible flexibility and investment security.

For camera manufacturers: Developing new markets with VisualApplets Embedder

- With smart cameras you have the possibility to develop new customer segments, whose requirements exceed off-the-shelf and existing OEM solutions considerably

- Your customers get offered the added value to program cameras within a per-determined frame by themselves without opening a support trap

- With VisualApplets, your own internal development can be accelerated to offer camera series with enhanced additional functionalities

- You can use VisualApplets for the acceleration of your own internal development to offer customers a camera with application specific additional functionalities

- Once developed, applications can be ported to different camera series

For end-users: Your personal way to a smart application camera

- You adapt your own image processing fast and flexible designs to your respective market requirements

- Enhancements of the camera functionality can be executed by yourself with low effort and without hardware programming knowledge

- the quantity of image data to be transferred and analyzed can be reduced by pre-porcessing to relieve the PC at final analysis

- Due tot he data reduction, the robustness of the image analysis and the inspection speed increase considerably

- By the lesser data quantity you can also use cost-saving interfaces alternatively such as Gigabit Ethernet

- The intellectual property can be secured by a sophisticated encryption system. The FPGA is protected against the read-out of the content, and reverse engineering data hacking is almost impossible.

Pricing, Availability and Ordering

- Concurrent EDA is a US Reseller for Silicon Software.

- Currently Available to US customers only.

- Please email Ray at

This email address is being protected from spambots. You need JavaScript enabled to view it. with questions / quotes / orders.