Can Your Machine Vision System Handle

10 G at the Edge?

Why 10 Gb/s, 25 Gb/s, or 100 Gb/s?

High-speed data interfaces are essential in today’s machine vision and automation systems. A single 4-lane MIPI camera can output 10 Gb/s of image data, while CoaXPress (CXP-12) cameras deliver 10 Gb/s per lane, supporting up to four lanes per camera. These data rates not only support high-resolution, high frame-rate imaging but also reduce latency per frame — a critical advantage in real-time control systems where tight sense-compute-communicate-actuate loops are necessary for precision in factory automation and robotics.

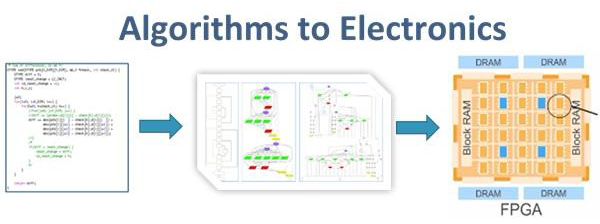

While modern PCs — oftentimes augmented with GPUs — are sometimes used in high-speed, high-data rate applications, FPGAs offer a more compact and cost-effective option for powerful processing.

Why Not Just Use a PC?

While modern PCs can support 10 Gb/s networking, they are often impractical for embedded industrial environments for three key reasons:

|

Why Use a System-on-a-Module (SoM)?

Adaptive compute SoMs — combining CPUs, FPGA logic, and 10–100 Gb/s interfaces in a single compact module — are an ideal solution for high-performance embedded applications.

|

How Do You Choose the Right SoM?

With more than 500 SoMs available — varying by performance, I/O, size, and power — how do you choose the right one? We can help. Our engineers will guide you to the best solution, whether you're targeting 10 Gb/s, 25 Gb/s, or even 100 Gb/s applications. If an off-the-shelf SoM doesn’t meet your needs, we can have a custom module created for your product. We specialize in embedded high-speed systems and are here to ensure your success, especially at 10 Gb/s and beyond. Schedule a call with an engineer at Concurrent EDA.

Distributed by Concurrent EDA, LLC

Pricing, Availability and Ordering

Email