Custom Machine Vision Design Services

Using FPGAs and SoCs

Whether for high-speed food and beverage inspection, baseball pitcher analysis, or real-time additive manufacturing monitoring, systems integrators today need powerful machine vision cameras capable of increasingly high frame and data rates. Concurrent EDA can deliver real-time processing within the camera, whether it’s your camera or other off-the-shelf high-speed cameras.

We’ve been transforming software algorithms into high-performance FPGAs and SoCs that process data from 1 to 100 Gb/s for nearly 20 years. By leveraging powerful FPGAs in lieu of CPUs and GPUs, systems integrators and OEMs can:

- Reduce design costs and improve time to market

- Run intricate, compute-intensive applications on a single board

- Get real-time vision processing up to 50 Gb/s

- Deploy complex algorithms inside a camera

- Launch powerful edge AI applications in a compact form factor

Below are some of the ways that Concurrent EDA can help drive advances in your high-speed, high-data rate machine vision applications. If you have further questions, reach out to set up a meeting here.

Concurrent EDA Recognized by AMD

as an Elite Adaptive Computing Partner

FPGAs have evolved from being part of a system to functioning as highly adaptive independent systems containing FPGA logic, multiple ARM CPUs, and advanced AI Engines. These powerful yet power-efficient devices deliver unprecedented flexibility and compute capacity. AMD has recognized Concurrent EDA’s skills as an Adaptive Computing Partner at the “Elite” level. “Our success is our customer’s success. That has been our mission for 18 years and still is,” says Dr. Ray Hoare, Concurrent EDA’s CEO.

Processing Within the Camera at 40 Gb/s

Machine vision cameras process data from image sensors, apply enhancements, and transmit it to a host PC via CoaXPress, Ethernet, USB, or CameraLink. High-speed cameras such as GigaSens allow user-defined processing at up to 50 Gb/s directly within the camera. Our engineers can help embed your algorithms into a GigaSens camera, creating a custom OEM solution tailored to your application.

Additionally, we can design custom cameras using any commercial image sensor, many of which are already available on a board.

Processing in the Frame Grabber at 40 Gb/s |

||

|

Achieving processing speeds of 40 Gb/s is possible with custom logic implemented in the frame grabber, a feature that turns any camera into a customized device using 1-, 2-, or 4-lane CoaXPress or Camera Link. |

|

|

||

Processing at the Edge |

||

AMD’s new Embedded+ platform combines a Ryzen Quad-Core CPU running Linux with a Versal FPGA featuring FPGA logic and AI-specific tiles for edge computing. This compact 7" x 7" x 3" system consumes under 50 W and functions as a mini-PC with a customizable I/O card. One variant supports up to eight GMSL cameras. We’re here to customize this platform to suit your specific requirements. |

|

|

|

|

||

Processing in a System-on-a-Chip FPGA

Modern FPGAs incorporate multiple ARM CPUs capable of running Linux, effectively replacing a PC in a compact form factor. We sell more than 500 FPGA modules, including the cutting-edge Versal adaptive compute devices that combine CPU, FPGA, and AI capabilities. Want a customized OEM module? Not a problem.

Custom Design Using FPGA + Camera Modules

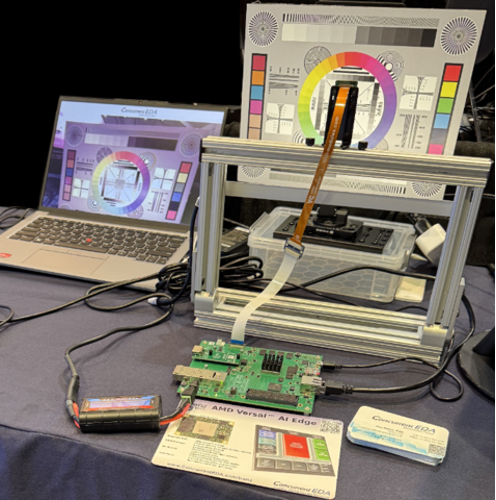

Concurrent EDA also provides algorithm porting services for your FPGA platform, a service regularly used by OEMs and defense organizations. For example, at Photonics West 2025, we demonstrated an MIPI-CSI2 sensor attached to a Versal FPGA that sends image data over Ethernet to a laptop that displays the image. Color correction and improvement can be executed on the Versal or the computer. The total power for the FPGA development board and image sensor was demonstrated at 10 W.

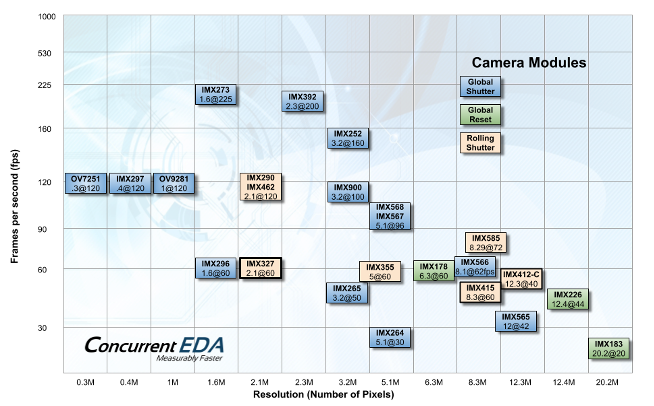

Jump-start your design with a Vision Components camera module that contains a standard MIPI-CSI2 interface and a well-defined control interface. For moving objects, use a global shutter to expose all pixels simultaneously or a global reset for high-resolution images up to 20 MP. For slow-moving images, cost-optimize your design with rolling shutter imagers. All sensors can be ordered in low quantities with a 1,000-piece discount. Contact us for more details and pricing, as Concurrent EDA is a Vision Components distributor and design agent.

Contact Us

Email